QFD: What’s behind Quality Function Deployment?

If a company wants lasting success, they must invest in their quality assurance. Only this way can they ensure that customers won’t jump ship and will continue to be satisfied with the products and services offered. Quality Function Deployment (QFD) is an incredibly helpful method in this area. So, how can you use this technique to move your company forward?

Definition and explanation of QFD

Quality Function Deployment (QFD) is a systematic analysis of customer requirements that is used to improve the quality of your products. QFD originated in Japan in the 1960s and 70s and was primarily developed by Yōji Akao. Mitsubishi and Toyota, as well as many other companies, have used this method to better tailor their products and services to their target market and accelerate growth. As part of this method, customer requirements, product performance, and the products offered by the competition are all taken into consideration.

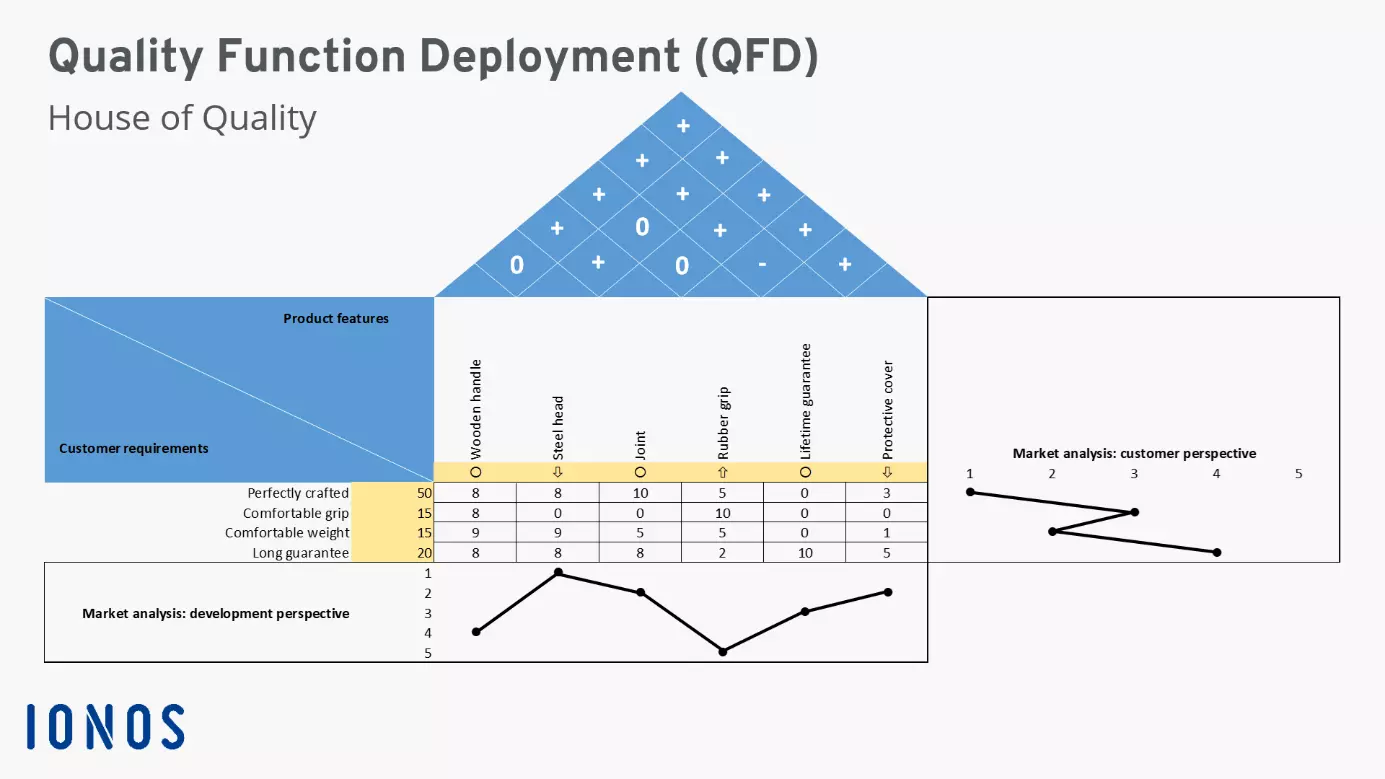

The distinctive characteristic of the Quality Function Deployment method is that all elements are brought together in a graphic and positioned in relation to one another. When you give the QFD matrix a specific form, this representation is referred to as a house of quality. This technique allows you to systematically work out customer requirements and then present them in a clear way. QFD is mainly used in quality management, but it is also used in product management and product development. Ultimately, this method involves all areas of the company.

The Quality Function Deployment method is structured in such a way that you can also use it for quality management in accordance with the standard ISO 9001.

The aims of Quality Function Deployment

The main aim of QFD is to improve a product or service so that it will be better received by the market. The focus here is also on customer satisfaction. Ideally, it’s best to apply QFD during the product planning phase, but you can also make adjustments to the product later on the basis of a QFD analysis.

With the Quality Function Deployment method, the features of a product or service are looked at individually. QFD is based on the idea that even small changes can have a big impact on market performance. Quality features are then derived from the customer requirements. These features are then transformed into process characteristics. QFD also aims to adapt the production processes. As opposed to other quality assurance methods, QFD involves all areas of the company. This means that the changes made can also have a direct impact on marketing and sales.

Another advantage of Quality Function Deployment – when implemented early and effectively – is that it can reduce development costs and times. As this method focuses on customer requirements with a well-thought-out method and is not based on assumptions, you can use it to make specific plans. Not only does QFD support companies by helping them to increase their revenue, but it also helps them to work in a more streamlined manner during production.

How exactly does the QFD method work?

Quality Function Deployment is not a rigid, fixed model. It has undergone many further developments since it was first used by Yōji Akao (e.g. such as those implemented by Bob Kind or Emil Jovanov). Even Akao himself believed that it was incredibly important for each person to adapt the concept to their own situation. Something that all variants of the method have in common is that they proceed step by step, starting with a customer survey and finishing with production or the product launch.

Step 1: target group analysis

The first thing to ask yourself during the product development phase is who the product is aimed at or who will buy it later. You must also think about the distinction between B2B and B2C – a relatively banal subject. Next, you must consider information such as income, gender, marital status, age, and level of education. Finally, you may have to make some assumptions about details that are more difficult to measure, such as the requirements, standards, and values of potential customers.

This first step can help you in two ways. First, it allows you to get a clearer idea of how the product or service should be positioned in the future. It also helps you to prepare for the next step, where you will look more closely at the target group.

Step 2: customer analysis

Now it’s time to survey customers. You will have already determined your target group (i.e. how you will put your sample group together) in the previous step. Now, you must find out what exactly potential customers want from a product or service. Interviews and questionnaires are particularly effective here. The QFD model can be used both for the initial development of the product and for any later adjustments. This also means that any complaints, guarantee claims, or customer support reports can be taken into consideration during the analysis. If the manufacturer or service provider does not sell their products or services themselves, it’s also a good idea to speak to the distributors. A good complaint management system can also help to provide some preparatory work for the QFD method.

The information collected also depends on the nature of the products or services offered. A service is evaluated differently to a product, and the details that are interesting for a QFD analysis can vary between physical items and software, for example. This way, certain features can be determined, as can the dimensions or colour. Equally important, regardless of the type of product or service, is the willingness to pay: how much would a customer be willing to pay for a certain product?

Often, customers themselves are not sure exactly what they expect from a product. As such, questionnaires and interview questions must be cleverly prepared beforehand. If in doubt, you can use the services of a professional market research institute to obtain meaningful results.

So as not to get lost in all the individual customer requirements, you should weight them. Requirements that are repeatedly expressed by customers get a higher priority. To do this, use a scale from 1 (not important) to 10 (very important). Another weighting method is to use an overall score. Start with 100 points in total and then distribute the points to the different requirements with different weighting.

Step 3: competitor analysis

The next step is to look at your competitors. The best way to do this is to select around five competitors that are most like your own company and then examine them with regard to the findings obtained during the customer requirement analysis. Here, the perspectives of the customers are decisive: does the competing product have the desired functions, the right weight, or the required durability?

You must evaluate your own product in direct comparison with the competition. How does the product or service perform in terms of customer requirements on the market? For example, all examined products and services can receive points or grades. This evaluation then produces part of the QFD matrix.

Step 4: product analysis

It’s also important to carefully examine your own product to make sure that it meets your customers’ requirements. To do this, you must first define the relevant characteristics of the product. You can also weight the individual performance characteristics if a distinction needs to be made between the characteristics. Now, you must examine how the product performs for each requirement. The technical specifications are also considered here. For example, if customers want a faster electrical object, you must take a closer look at the motor.

However, it doesn’t just stop at a simple assessment if the company also wants to improve their product. Therefore, the optimisation potential of the product must also be taken into consideration: what can be changed in production to produce a better product (i.e. one that is orientated to the customers’ requirements)?

At the end of the Quality Function Deployment process, a clear catalogue of measures will be produced. The knowledge gained must now be communicated and implemented in product development, product management, production, sales, and marketing.

Example of a QFD matrix

To make things clearer, we will now go through all the aforementioned steps with a simple example and put a QFD matrix together at the end. For example, imagine that you want to put a new hammer on the market. First, you must define your target group. This naturally includes carpenters but also DIYers. You might therefore collect the following characteristics:

- Men and women over the age of 20

- Mid to high income

- Professionalism and durability are very important to the target group

From this group, you must now select as diverse a range of test subjects as possible for the customer analysis. Use questionnaires to find out what your customers’ requirements are and which characteristics are the most important to them:

- Perfectly crafted (50 points)

- Comfortable grip (15 points)

- Comfortable weight (15 points)

- Long guarantee (20 points)

As customers want the product to last practically forever, they would be willing to pay a higher price.

Next, you must compare your product with that of your competitors. The test subjects selected from your target group can help here too, since your customers’ opinions must remain at the forefront of your considerations. Note down whether your hammer performs better, worse, or the same for the different requirements.

Finally, the components of the hammer must be examined even more carefully. Let’s imagine that your hammer has the following characteristics:

- Wooden handle

- Steel head

- Joint

- Rubber grip

- Lifetime guarantee

- Protective cover

You can now enter all the information collected in the QFD matrix and build a house of quality.

In the example above, we have added the market analysis with regard to the customer requirements and the product’s characteristics. The house of quality’s roof is formed by the relationships between the different product characteristics. In our example, you can see that further development of the rubber grip would have a negative impact on the lifetime guarantee. From this, you can infer that this is a weak point.

QFD can give you plenty of ideas as to how you could improve your product or service simply from the information collected. The QFD matrix shows all the information at a glance, and you can learn even more from it. For example, many people also like to include specific technical target values. You can find more information about putting together a QFD matrix in our detailed article on the house of quality method.

If you are not looking to optimise an individual product but instead would like to work on continuously improving your entire company, you could try using the Continuous Improvement Process (CIP).